OEE Monitoring on Ignition 8.1 SCADA for a N95 masks manufacturing unit in the USA

Business Case

- A Multinational Conglomerate wanted to implement IIoT solutions for one of its N95 mask manufacturing unit located in the USA. Sarla Technologies was chosen by a global IT company to provide scalable end-to-end data connectivity solution from plant floor to analytics platform including OEE dashboard development.

- The project involved:

- Data aggregation from multiple plants at central location.

- OEE dashboard development and alarm monitoring at central location.

- OEE calculation for each machine in the plant.

- Integration of central data aggregator with Analytics software (using Kafka) to share plant data.

Systems and Tools

-

- Ignition 8.1

- Ignition SDK

- IIoT – Cirrus Link MQTT modules

(Distributor, Engine and Transmitter) - Matrikon Flex Dispatch Data broker

- Kafka

Project Scope

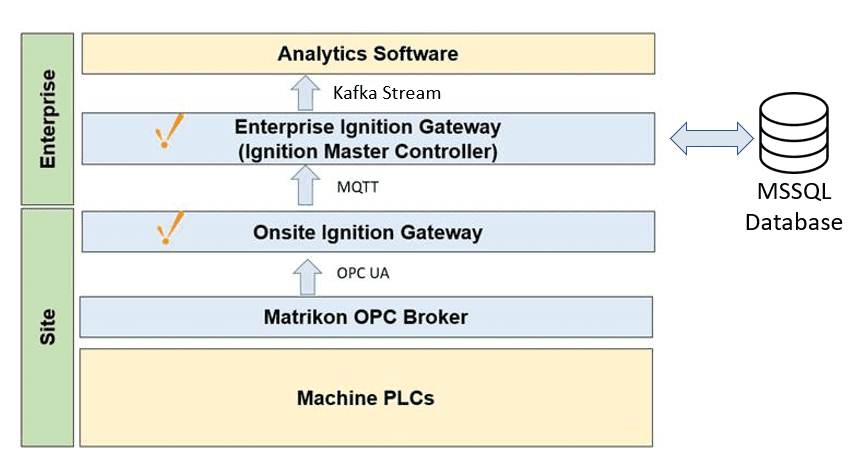

- Installation and configuration of Matrikon OPC Broker to facilitate data transfer between Plant PLCs and Onsite Ignition Gateway.

- Installation and configuration of Cirrus Link MQTT Transmission module on Onsite Ignition gateway to publish data to the Enterprise Ignition gateway.

- Installation and Configuration of Cirrus Link MQTT Engine and Distributor module at the Enterprise Ignition gateway to receive data from multiple plants.

- Custom development of OEE calculation engine on Ignition platform using python scripting, tags & transaction module.

- OEE dashboard development and implementation of OEE calculation engine for each machine in the plant at Enterprise Ignition Gateway.

- Custom Ignition module development for converting data into Json format to transfer it using kafka stream.

- Integration between Enterprise Ignition gateway and client’s analytics platform for data analysis.

- End-to-end data connectivity from plant floor to analytics platform with scalable model.

Related Success Stories Of Software Development

Laboratory Information Management System for Leading Chemical Company in India

Automatic Material Handling System for Leading Pharmaceuticals Company UK

Gluing Beed Detection Application Development for Leading Automotive Company, Germany

Remote Monitoring Solutions of Water bodies using Cloud Managed Service, The Netherlands