Automation of Final Assembly Line for an Electric Vehicle Manufacturer in the USA

Business Case

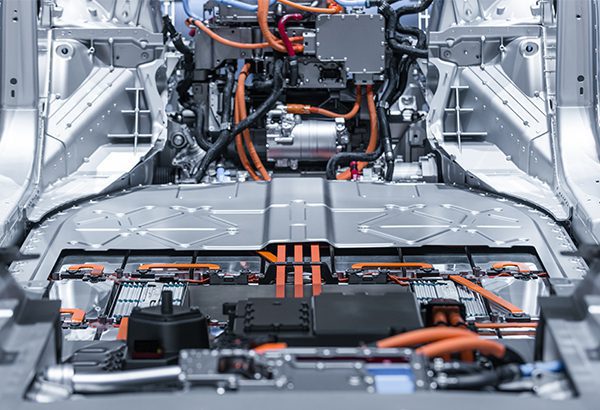

- Leading Electric Vehicle manufacturer in the USA wanted to automate its Final Assembly Line comprising door assembly, wheel assembly, driveline assembly and marriage line to increase the capacity. Our Automation Engineering team led this greenfield project right from prototype development to final assembly line handover including production support

- The overall project included 10,000+ I/O’s, 55 Siemens PLCs, 2 Ignition SCADA Servers and 15+ clients.

Systems and Tools

- Ignition SCADA 7.8

- Siemens Control System:

-

- CPU 1516pro F-2 PN (ET200 Pro CPU based on 1500 series)

- CPU 1518F-4 PN/DP

- TIA V15

- Siemens Drives:

-

- Siemens S120 Servo Drives

- Siemens G120 VFD’s

- Vision System & Scanners: Cognex

- RFID- Balluf

Project Scope

Onsite – USA

- Prototype Section PLC & SCADA Development

- PLC standard library development for all PLCs

- Prototype Section testing & commissioning

- Deployment on actual automation system for final assembly line

- Commissioning of conveyor, lifters (Shelf lifter, Post lifter, ASRS), battery assembly line, skid roller table

- RFID based data tracking

- Commissioning of safety devices (Sick area scanner, light curtain) & drives (SEW & Siemens)

- Ignition SCADA server setup & configuration

- Established Ignition communication with MS-SQL Database

- Developed Script to calculate OEE and Downtime

- Alarm configuration and user mapping

- Robot-PLC integrated testing, Auto sequence testing & Cycle time optimization

Related Success Stories Of Automotive Industry

BIW Line Program Development and Commissioning for Major Automotive Company, India

CNC- Installation & Commissioning for Leading Automotive Company, Shanghai

Programming Support for Glue Dispensing Machine for Leading Automotive Manufacturer in China

Dispensing Application- SPM for Largest Automotive Company, Germany

Design & Development of Infinite Buffer Assembly line for Leading Automotive Company, USA

Commissioning and Production Support for Leading Automotive Company, Mexico

Automation Engineering for Leading Automotive Company, Fremont, California

Automation Engineering for Assembly line for Leading Automotive Company, France